Over 2,000 Australians die each year as a result of exposure to hazardous substances while at work, according to Job Safe SA. At Webforge, we make a number of products, including fibre reinforced plastic, specifically designed to withstand the impact of dangerous and corrosive chemicals, so we know how important safety is in this sort of working environment. With this in mind, we've made this handy guide to working with dangerous chemicals.

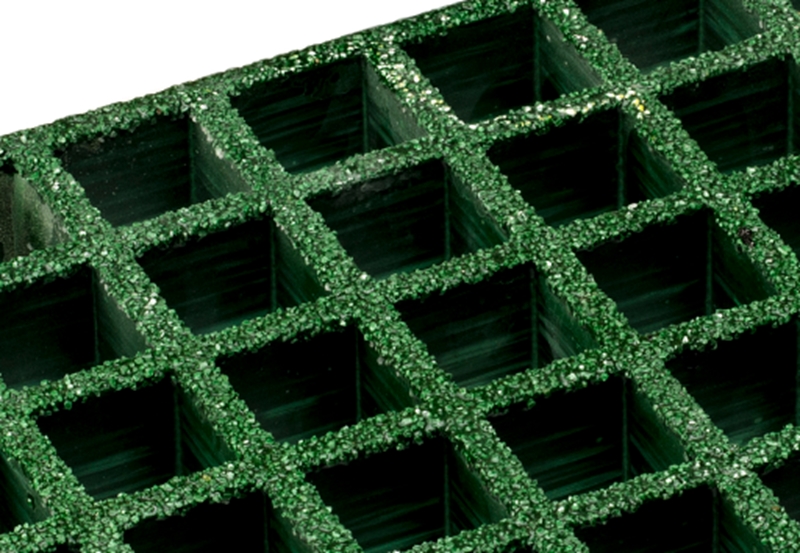

Our Fibre Reinforced Plastic grating is highly resistant to corrosive chemicals.

Our Fibre Reinforced Plastic grating is highly resistant to corrosive chemicals.So what exactly is a dangerous chemical?

Up to 40,000 chemicals are currently used in Australian workplaces, according to the Union of Occupational Health and Safety Representatives. These come in many different forms, but Safe Work Australia defines them as "substances, mixtures and articles that can pose a significant risk to health and safety if not managed correctly. They may have health hazards, physical hazards or both."

Dangerous chemicals can include anything that's toxic, substances that are linked to cancer and corrosive chemicals that could cause skin damage. Any substance that may react to its environment in an adverse way, for instance if it's flammable or likely to explode, is also classed as a hazardous chemical.

What steps can you take to keep safe while working with them?

1) Know your labels

Each substance you work with should have a hazardous chemicals label clearly placed on it in an appropriate position. As detailed by Safe Work Australia, these will identify:

- What the product is

- The name and contact details of the manufacturer

- Which ingredients are used to make up the chemical

- A pictogram - this will have signal words like "caution," followed by a hazard statement which will tell you why the chemical is dangerous, for example if it's flammable. A pictogram illustrating the hazard will also be present. For instance, there might be a skull and crossbones to indicate toxicity or poison, or an exclamation mark to signal that you should take precaution when handling the goods.

- Packaging normally includes information about the first aid and emergency procedures people should follow if anything does go wrong with the chemical. Often hazard labels will have an emergency phone number for treatment for specific or rarer poisons.

- A hazard label may also include an expiry date.

If your employees encounter a dangerous substance that isn't labelled properly, notify your suppliers and don't undertake the work until this gets resolved.

2) Understand the risks involved

When working with dangerous chemicals, it's essential that employers go through each task an employee might have to undertake and assess all the risks involved. Calculate how long staff are being exposed to the hazard, and ensure this is compliant with workplace exposure standards.

If you can, eliminate the risk altogether, and if you can't do this try to minimise it as much as possible. This could happen through shortening the length of time an employee is exposed to the substance, or making sure they have the right mask and equipment so that they inhale the chemicals as little as possible.

Ensure you're following the correct health monitoring procedures.

Ensure you're following the correct health monitoring procedures.3) Comply with all health monitoring regulations

The Australian government has strict guidelines in place for monitoring the health of employees while they're working with dangerous goods. Employers must pay for the medical examinations that are required by law for the duration of time an employee is working with a hazardous substance. Employers are also required to regularly consult with their staff about these health checkups and obtain a report from the medical provider. They should also provide a copy of this report to their staff member as well as keeping one for themselves.

At Webforge, safety is one of our main concerns. That's why we provide walkways, barriers and other safety solutions for a variety of workplaces. Please contact us for more information.